Engineering Facilities

State-of-the-Art Infrastructure to Meet Your Engineering Need

At RELIABLE, our advanced infrastructure is designed to cater to diverse engineering requirements with precision and efficiency. From cutting-edge design tools and high-performance laser cutting machines to robotic welding setups and versatile machining centers, our facilities are equipped to deliver exceptional quality and innovation. With a commitment to excellence, we ensure every project is executed seamlessly, meeting the highest industry standards.

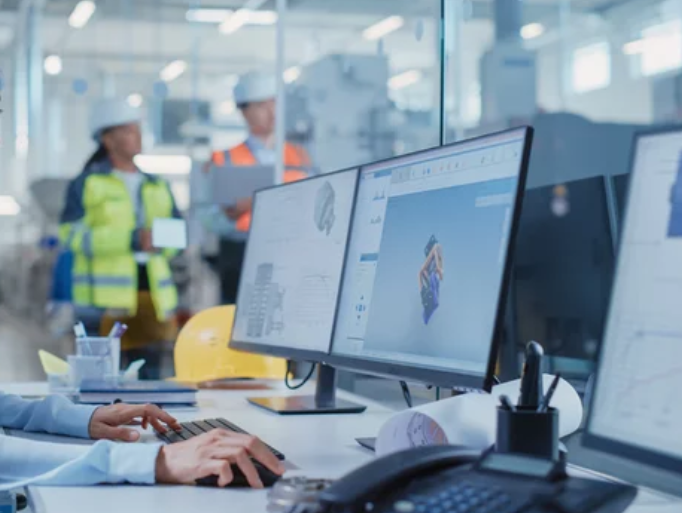

Design Center

Our advanced Design Center is equipped with cutting-edge 3D modeling, 2D drafting, and simulation software, enabling precise and efficient engineering solutions. Staffed by expert engineers, we specialize in sheet metal fabrication, machining, casting, and prototype development. From creating detailed models to generating laser nests, bending programs, and conducting simulations, our Design Center ensures seamless integration from concept to production, delivering high-quality, tailored solutions.

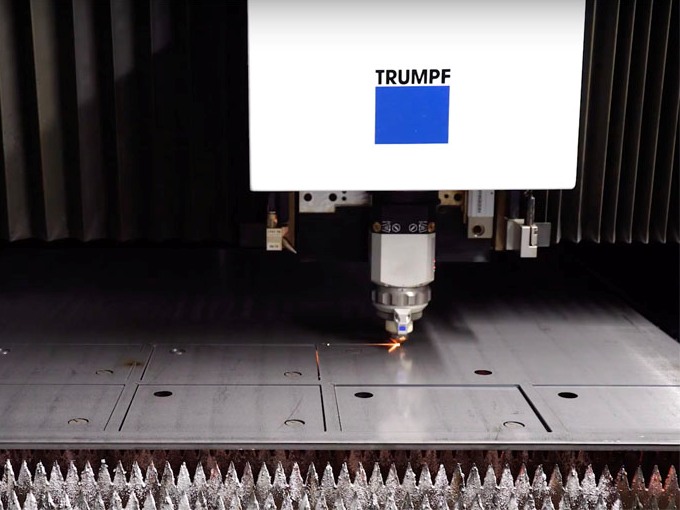

Laser Cutting

Facility having Trumpf Laser Cutting Machine 1030 is a high-performance solution capable of cutting materials up to 25mm thick with precision and efficiency. It handles a wide range of materials, including mild steel (MS), stainless steel (SS), brass, copper, and aluminum, ensuring versatility for diverse applications. This advanced machine guarantees superior cut quality, enabling us to meet complex design requirements with speed and accuracy.

Advance CNC Press Brake Bending

Our facility have Amada Press Brake HRB2204 is a powerful and precise bending solution with a 4-meter bed and a capacity of 220 tons. This advanced machine enables us to handle a wide range of sheet metal bending tasks with exceptional accuracy and efficiency. Its robust design and versatility make it ideal for meeting complex fabrication requirements.

Advance Fanuc Robotic Welding Setup

Our FANUC Robotic Welding Setup combines advanced automation with precision to deliver consistent, high-quality welds. Designed for efficiency and repeatability, this state-of-the-art system is ideal for handling complex welding tasks across various materials. With its superior accuracy and speed, it ensures enhanced productivity and meets the demands of modern fabrication processes.

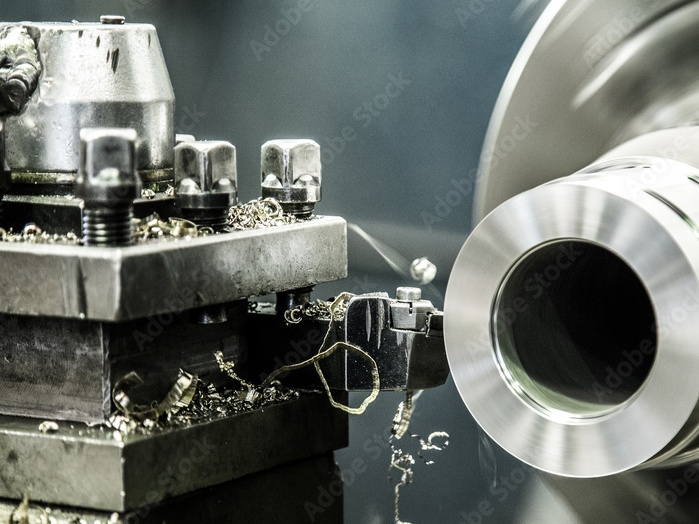

Inhouse Toolroom for Dies Manufacturing

We have inhouse Toolroom setup ready for complex parts dies development. This enables to design and develop stamping dies in very short time and deliver in no time! From Blanking, Draw, Hole piercing to Embossing etc, every stamping feature can be made with inhouse toolings.

Lincoln Welding 450 WE Setup

We have Lincoln 450 WE welding machines designed for high-performance and precision welding applications. With advanced technology and robust capabilities, these machines ensure strong, reliable welds across various materials. Ideal for complex fabrication tasks, they deliver exceptional quality and efficiency, meeting the highest industry standards.

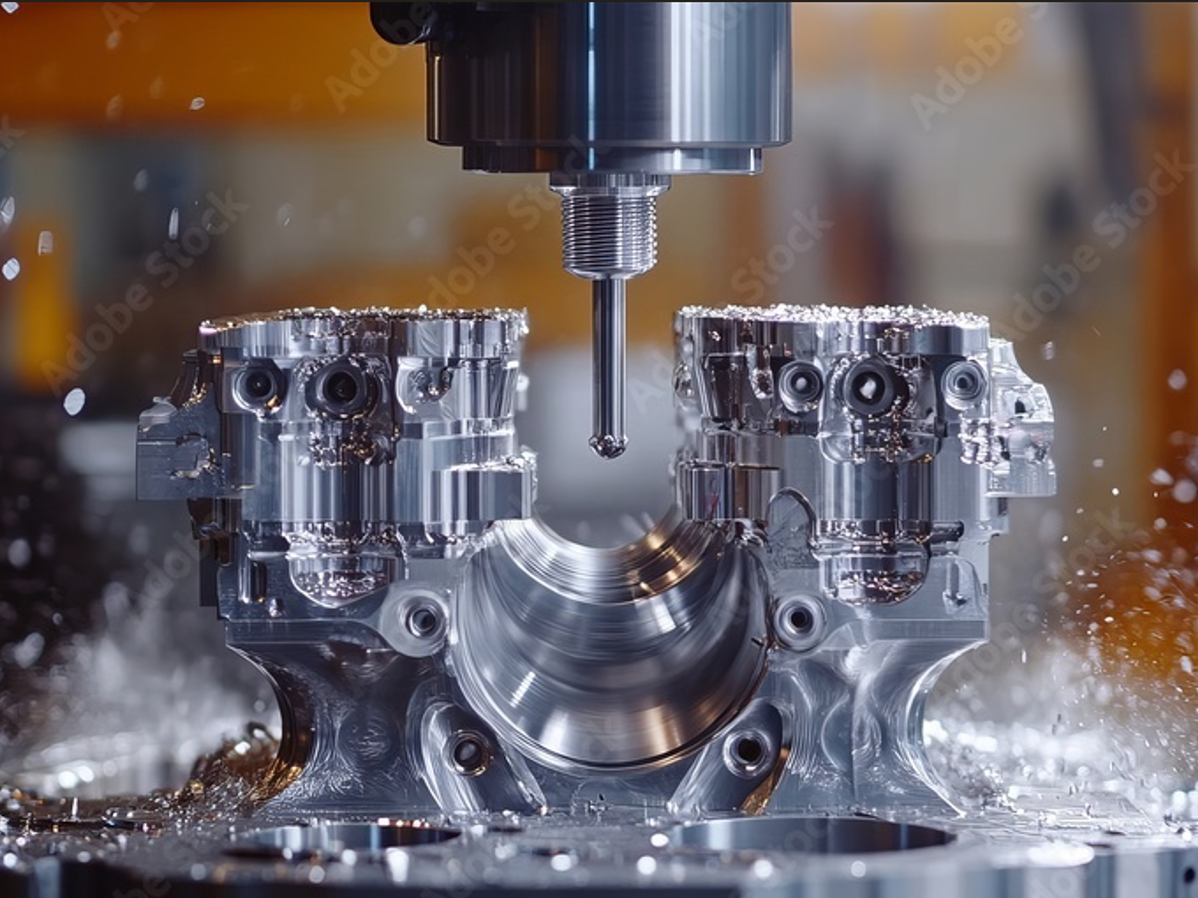

Precision CNC Machining Center

Our BFW XTRON VMC Machining Center is equipped with a spacious machining bed size of 1366x600mm, offering precision and versatility for a wide range of machining operations. This advanced setup ensures high accuracy, efficiency, and reliability, making it ideal for intricate and complex component manufacturing. Designed for superior performance, it meets the demanding needs of modern engineering and fabrication.

Inhouse Faro 2D probing and 3D Scanning

ARO Quantum BlueM Scanner offers unparalleled precision in 3D scanning and inspection. With advanced blue laser technology, it delivers highly accurate measurements for complex geometries and surfaces. Ideal for quality control and reverse engineering, this cutting-edge scanner ensures reliability and efficiency in meeting stringent engineering standards.