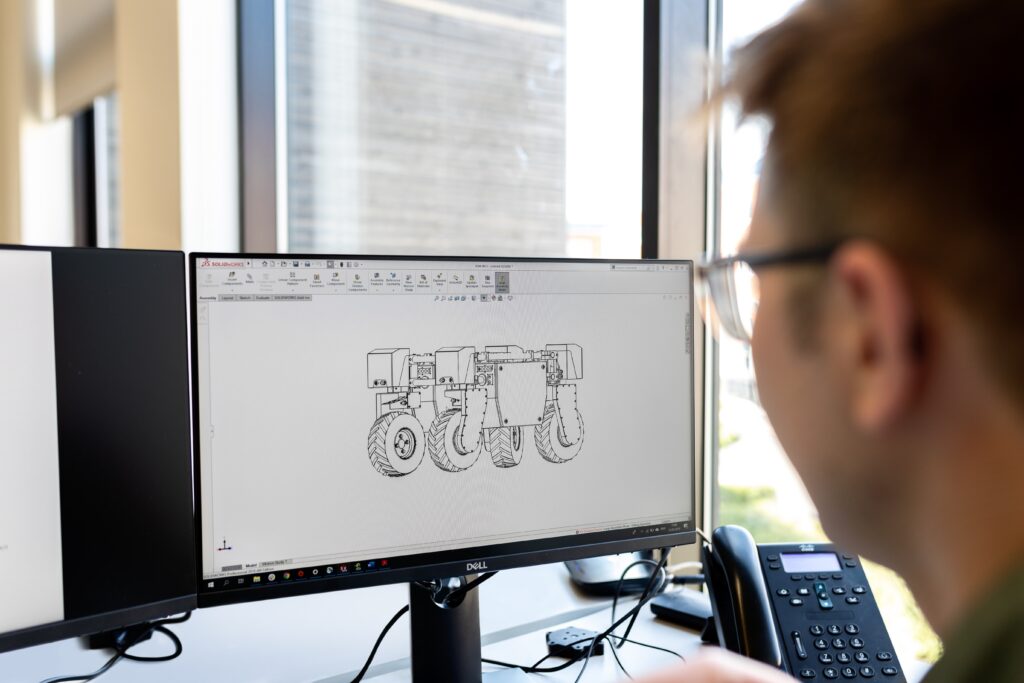

3D modeling for building life-changing innovations

At Reliable Engineering Services, our revolutionary engineers broaden manufacturable, cost-powerful new products. Our product improvement group plans every level of the product existence cycle-conceptualization, design, and improvement of components and components to offer a extremely good deliverable with a short turnaround. We get in which we want to head speedy and efficaciously with green data control and collaboration among teams.

Some of the key 3D modelling services we provide are as follows:

- Wireframe creation

- 3D feature-based modeling

- 3D sectional views and CAD models

- 3D model exploded assembly views

- 3D models/assemblies from 2D details/assemblies

- 3D rendering of full-fledged manufacturing drawings

- Solid modeling

3D Scanning/ Reverse engineering: Capture accurate CAD data of physical for your dream project.

Reverse engineering deliverable:

- Polygon models – STL, PLY, OBJ, VRML

- Point cloud data – color or non-color – PTS, PTX, XYZ

- 3D Surface model –IGES, STEP

- Hybrid CAD model (surfaces and solids) – IGES, STEP, ParaSolid, SolidWorks

- Feature based solid model & assemblies – IGES, STEP, ParaSolid, SolidWorks

- Photo realistic renderings

- Drawings & Animations

- Capture CAD data from your object

- Create a new part to fit

- Refine performance surfaces

- Redesign a product or part to eliminate production flaws.

- Make your productio process more efficient.

Easier, better, & safer legacy data conversion

We are uniquely suited to lead our clients through all phases of legacy data conversion to cloud adoption, since Reliable Engineering Services is based on a foundation of application development and software consulting expertise.

Offerings under Legacy Data Conversion are:

- Data digitalization (hard print conversion to digital format)

- Plant layout upgrade to As-Built layout (with site mark ups)

- Migration of design/ Drawings Platform

- Regeneration of vendor data

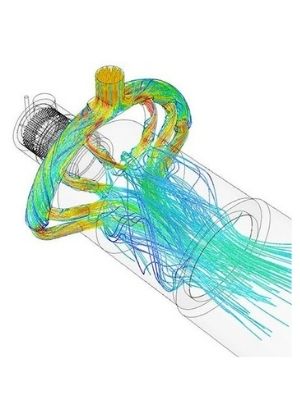

CAE/CFD

Companies all around the world are turning to Computer Aided Simulation to minimize time to deliver trustworthy goods, reducing the amount of physical testing and design revisions.

What we offer in CAE:

- Solution for molding problems

- Expert mold flow consulting

- Building expert mold flow analysts

Benefits of our CAE services:

- Improved part quality

- Faster cycle times

- Larger processing window

- Reduced “Fire Fighting”

- More economical benefits.

PLM Services

Product Lifecycle Management (PLM) enables organizations to introduce innovative ideas into the market place in the most efficient timely manner by utilizing integrated processes and systems from concept, through design, into manufacturing and service. Benefits of the new PLM system include the removal of paper, which has led to improved customer service with our services being ERP paperless company and information being integrated into the PLM workspaces.

Manufacturing PLM brings our clients and us together in a cloud-based digital environment, resulting in significantly reduced manufacturing times and time to market. Responding to RFPs, producing tech packs, quality testing, compliance paperwork, and other aspects of the R&D, product development, costing, and sampling process are all easier and faster to manage when using PLM rather than spreadsheets or a simple portal.